Resin 3D Printing Mistakes

How to Avoid Common Problems and Print Safely

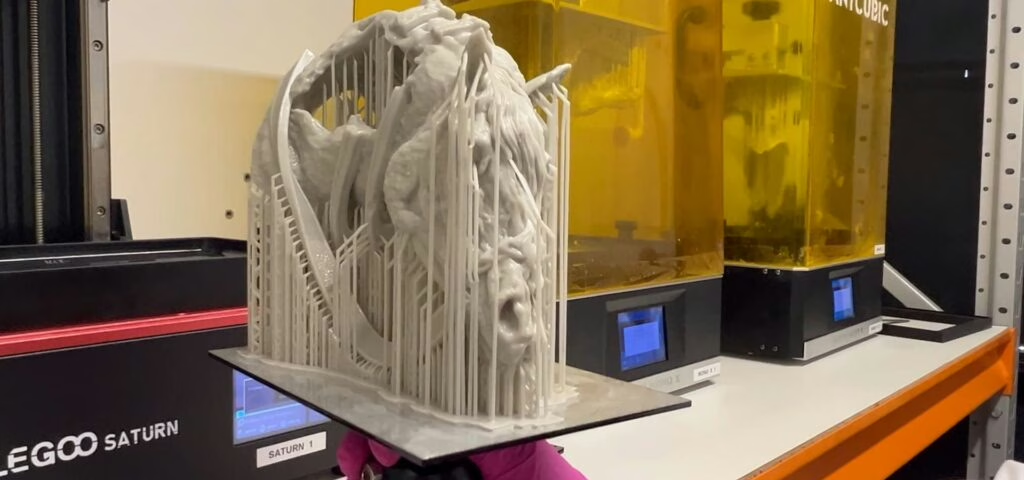

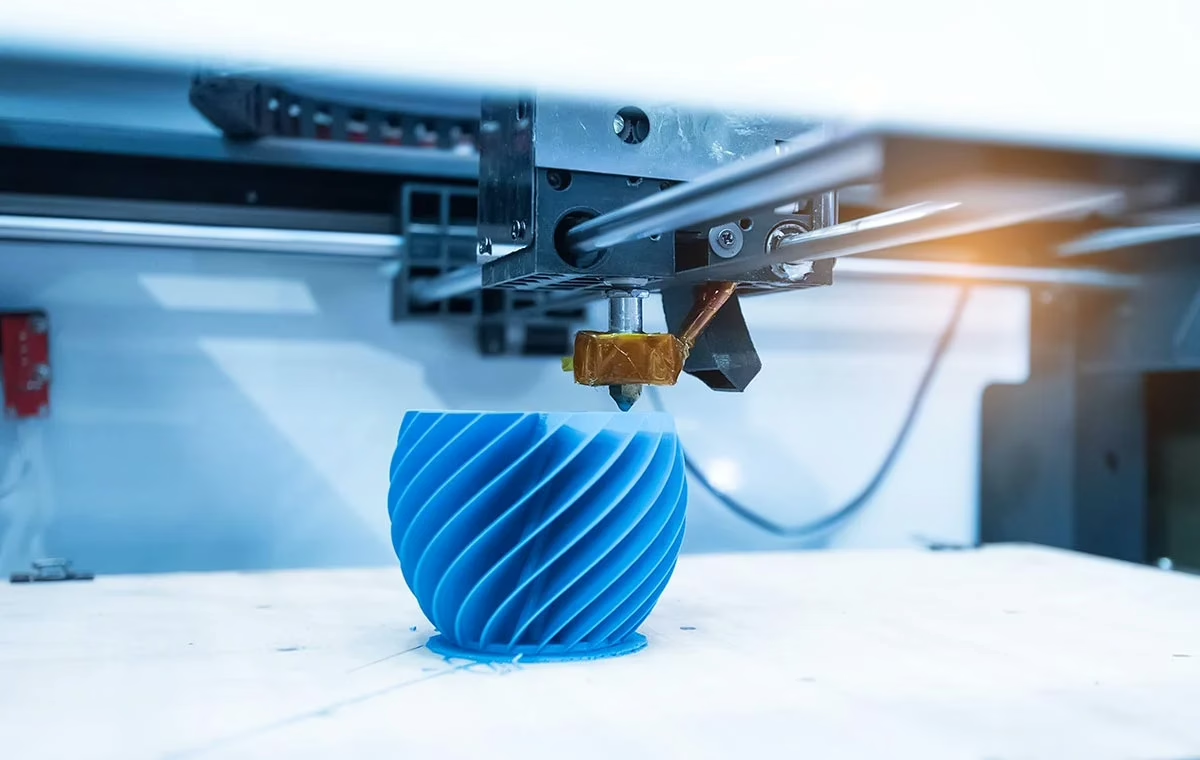

Resin printing unlocks amazing detail and smooth finishes, but it also comes with unique challenges. Many makers jump in without realizing how small mistakes can risk their health, ruin their prints, or even damage their machines. If you’ve ever wondered, “Why do my 3D prints keep failing?”, the answer usually lies in a few preventable habits. This guide breaks down the most common 3D printing mistakes with resin and shows you how to avoid them so you can stay safe, save resin, and get the results you want.

#1. 3D Printing Mistakes: Skipping PPE and Safety Basics

The #1 mistake is ignoring safety. Resin isn’t a monster, but it does require care. Nitrile gloves, protective goggles, and a proper respirator with organic vapor filters are non-negotiable. Don’t rely on the flimsy paper masks that come in printer kits: they do nothing against toxic fumes.

#2. Optimize Your Workspace: Ventilation and UV Protection

Good airflow is critical, but placing your printer in direct sunlight is a recipe for disaster. Both sunlight and some artificial lights emit UV, which can cure resin unintentionally. Test your workspace by leaving a drop of resin under your lights to see how it reacts. A dedicated, well-ventilated area with silicone mats, alcohol spray bottles, and paper towels on hand keeps everything safer and cleaner.

#3. 3D Printing Mistakes: Temperature and Resin Flow

Cold resin thickens and becomes harder to print, leading to failed layers even if calibration is perfect. If your printer doesn’t have a built-in heater, use accessories to maintain an optimal temperature. Stable resin flow equals fewer 3D printing failures.

#4. Accurate Resin Usage: Calculating and Margin Essentials

Never guess how much resin you need. Your slicer’s estimate is helpful, but it always allows for extra. You need a consistent layer covering the vat’s bottom, without overfilling and risking messy spills. A little planning saves resin and keeps your machine safe.

#5. 3D Printing Mistakes: Poor Calibration Habits

Calibration errors are one of the most common problems in 3D printing. Even if your friend uses the same printer and resin, your setup is different. Use community calibration tests, like the popular “Cones of Calibration,” to fine-tune your settings and avoid unnecessary waste. You can get access to a test and also improve your printing skills in Loot’s 3D Printing Hero Course (which is totally free).

#6. Preventing Print Failure: The Build Plate Security Checklist

Loose vats or plates cause failed prints and can scratch or puncture your FEP or LCD. Before every print, run a quick checklist: are the knobs tightened, the vat secure, the plate locked? It takes seconds and prevents expensive mistakes.

#7. Smart Vat Management: When to Clean, Not Empty

You don’t need to empty the vat after every job. If the resin is the same, just mix it gently before printing. For failed prints, use the “Clean Vat” function to trap particles in a thin cured layer you can remove. Emptying unnecessarily only wastes time and resin.

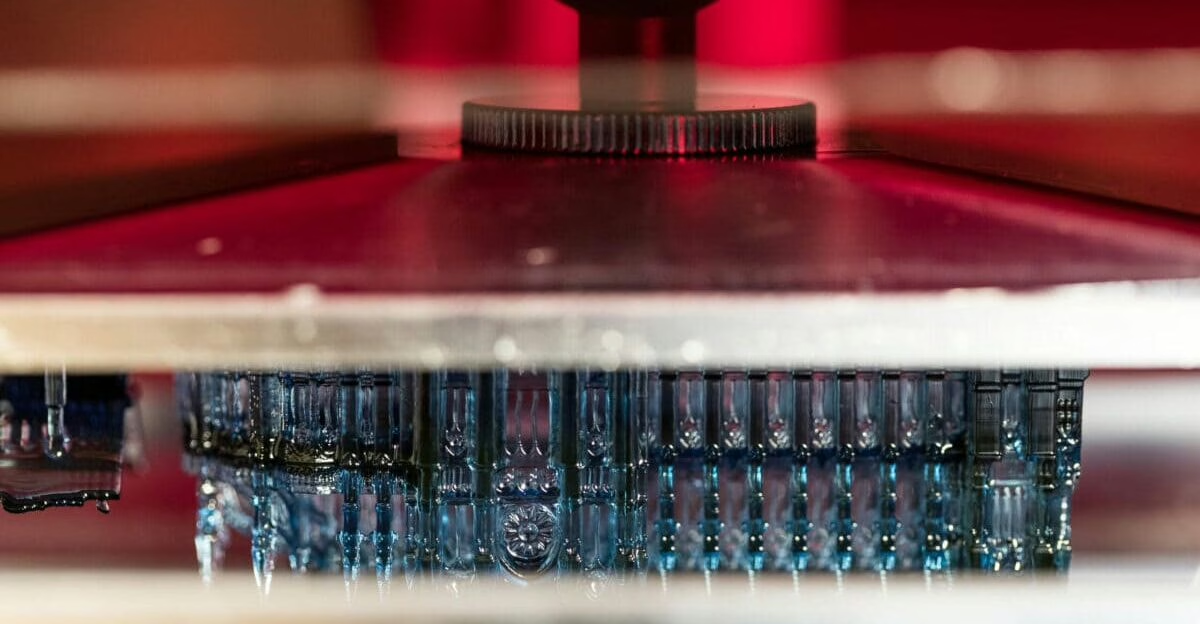

#8. Safeguarding Your Investment: Protecting the LCD and FEP

A punctured FEP can leak resin into your LCD and destroy it. A simple LCD protector, like a phone screen protector, can save your printer. Many brands even sell custom protectors. For extra protection, tape around the LCD edges and cover the acrylic lid with PVC film to block resin splashes.

#9. Mastering Post-Processing: The Two-Stage Wash Method

Even with wash-and-cure machines, a single alcohol bath gets dirty fast. Instead, wash prints in two stages: first in a “dirty” alcohol container, then in a cleaner one inside your machine. Finish with a quick spray rinse. This keeps models sharp and saves alcohol in the long run.

WANNA IMPROVE YOUR FINISHING? CHECK THIS VIDEO!

#10. Extending Printer Lifespan: Avoiding Wear and Tear

Always printing in the same spot stresses your FEP and LCD unevenly. Shift your models around the build plate to spread wear evenly and extend your printer’s life.

#11. Resin Printing Myths Debunked: Safety and Toxicity Facts

Many resin printing myths cause unsafe habits:

- Low-odor resin is not less toxic.

- Water-washable resin still needs safe disposal.

- Built-in carbon filters don’t remove harmful chemicals.

- Cured resin isn’t automatically food-safe.

Treat all resin with the same precautions, no exceptions.

Wrapping Up

Most 3D printing problems come down to preparation: PPE, proper setup, stable temperature, calibration, and careful handling. Avoid these mistakes, and you’ll reduce failed prints, protect your machine, and keep your workspace safe.

Resin printing doesn’t have to be intimidating. Respect the process, follow these tips, and your next project won’t just look great: it’ll be safer, too.

Loot Studios can help you tell your story. Choose your favorite bundle from our previous releases or sign up for Fantasy or Sci-Fi to receive a new bundle every month. You can also check out some tips on our YouTube Channel.

JP Lima is a writer, editor, TTRPG translator and overall fantasy and sci-fi enthusiast. He has been creating fantasy worlds for more time than he would like other people to know and has contributed to Brazilian magazines like Tempos Fantásticos, Mafagafo, Faísca and more. His favorite games with minis are tactical battle titles like Mice and Mystics and he loves gory, creepy and spooky figures.