Glossary of Resin 3D Printing Terms

The Ultimate Guide to the Hobby of the Future

“When printing, this model has been showing signs of bad adhesion on the build plate quite often. So, I think I need to either increase exposure time on my SLA printer, change the support structure – either on the software or the STL file itself – or just start looking into getting a new LCD screen”. Frankly, as the meme goes, this declaration should have been enough to knock Henry Ford out with psychic damage 100 years ago – well, either that or make Arthur C. Clarke weep with excitement.

What I mean to say is: we know 3D printing doesn’t look like an accessible hobby. It seems to have a considerable initial learning curve – and it has, just like any other activity in which you’d want to have good (or at least acceptable) results. The possibilities, however, far outweigh potential hardships. This post aims to provide a non-exhaustive and up-to-date list of the many, many terms, old and new, and their meaning inside the 3D printing universe. As evident from the title, the focus here is in resin – or more precisely, SLA printers (we’ll get to that!). While there are other 3D printing methods with, as always, their own pros and cons, using an SLA printer is currently the most efficient way of making superb and highly detailed miniatures for you regular RPG play sessions (as a completely, of course, random example).

But how do these printers work? SLA (stereolithography) is an additive vat photopolymerization process, which is a very fancy way of saying that it cures, layer by layer, one section of a determined object at a time. A special laser that emits UV lights performs this action. Once the laser cures enough layers of material on top of one another, you get your whatchamacallit.

405nm UV

The 3D printer emits a specific type of light to cure resins. You’ll often see “405nm” in a resin’s title or description, which shows it’s compatible with your printer. On an example of a purchasable resin container, you’ll see this “nm.” It stands for nanometer, or one billionth of a meter, which is the wavelength of UV lights. These lights have a frequency beyond the visible spectrum, and manufacturers chose them due to…eh, I’m digressing.

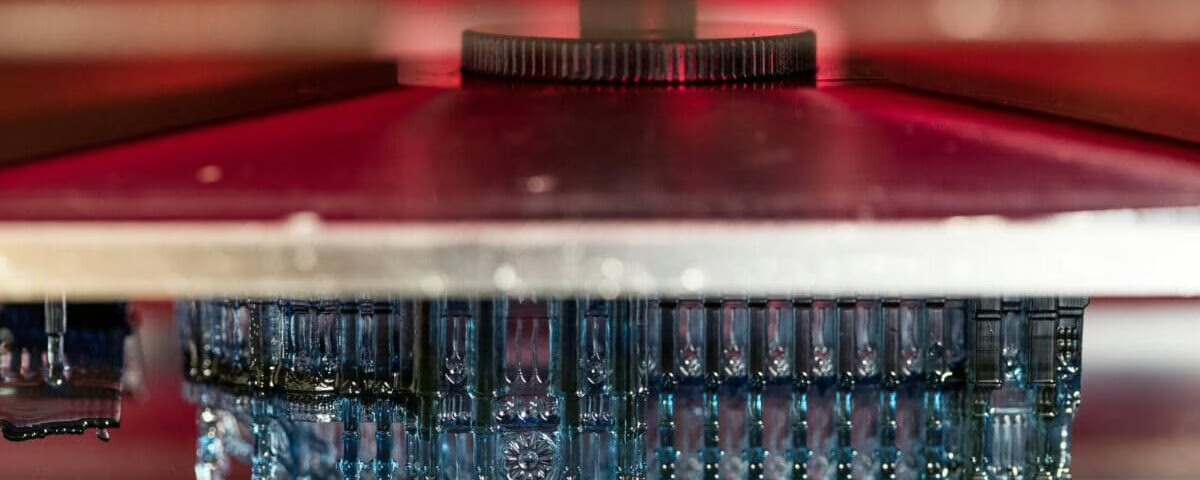

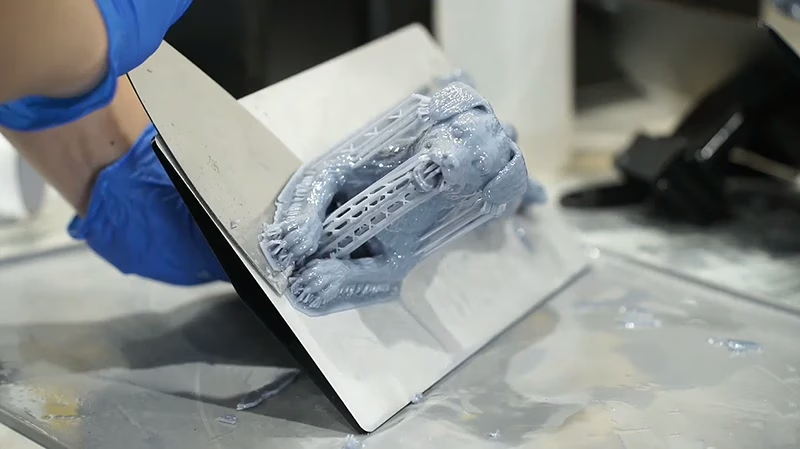

Build Plate

(Almost always a) metallic surface onto which the resin adheres to. This first layer is essential since the next ones will depend on it to manufacture the 3D object. It can be perforated or marked with ridges to provide better support.

This silvery part is where your resin first sticks to. A finished piece looks like the one on the right. Source: Al Williams, Hackaday.

CAD

Computed-aided Design, both in 2D and 3D, refers to using programs to design, draw, model, and sculpt digitally.

CAM

Computer-aided manufacturing is the process of using special software to manufacture objects. 3D printers, CNCs, and laser cutters are some of the most popular ones that see home use.

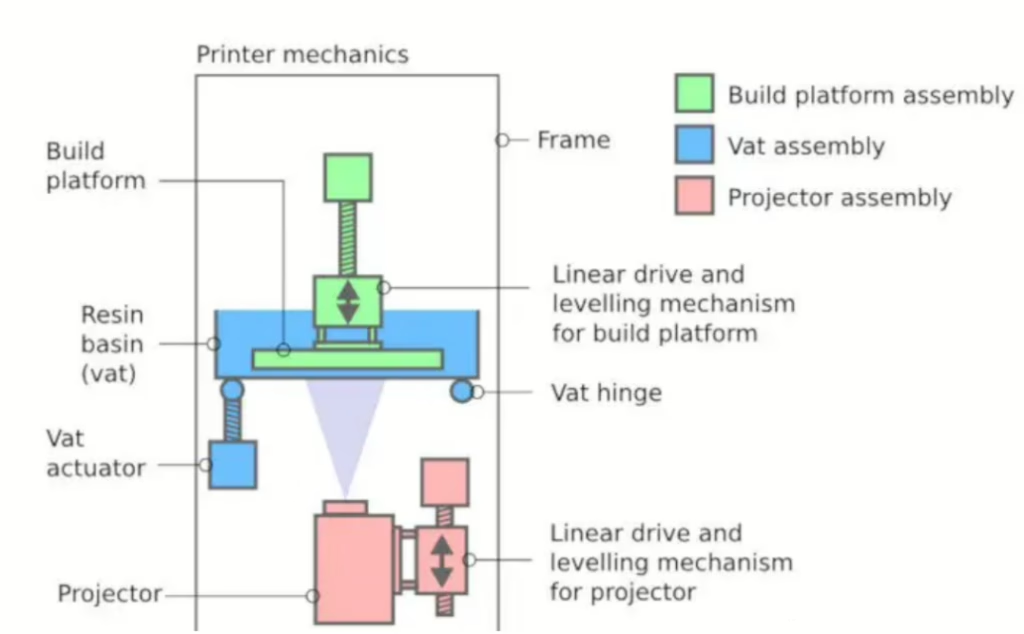

DLP

Digital Light Processing is another type of resin 3D printer. It uses a projector to create voxels in the resin tank.

Schematic of a DLP printer. If it looks complicated, it’s because it is. If it does NOT look complicated, Dunning and Kruger would like a word.

Exposure Time

The period during which the resin is subjected to UV light to cure. The more exposure time it gets, the harder it will be (with lots of caveats). First layers, for instance, get more seconds of it.

FEP Film

Fluorinated Ethylene Propylene films are the standard for resin printers. These films stretch over the vat, contacting both the resin and the UV light generator. This position enables the light to pass through during the curing process. They also have good chemical resistance and non-stick properties.

Layer

2D section cut from part of a model. What usually gets polymerized at once?

Layer Height

One of the ways to measure the “resolution” of a 3D printed object. The smaller the layer height, the more details you can cram into the same model. SLA printers usually measure theirs in microns (or 1/1000s of a millimeter, mm).

Levelling

Aligning the Built Plate with your LCD screen or vat ensures a uniform curing process and adherence.

LCD

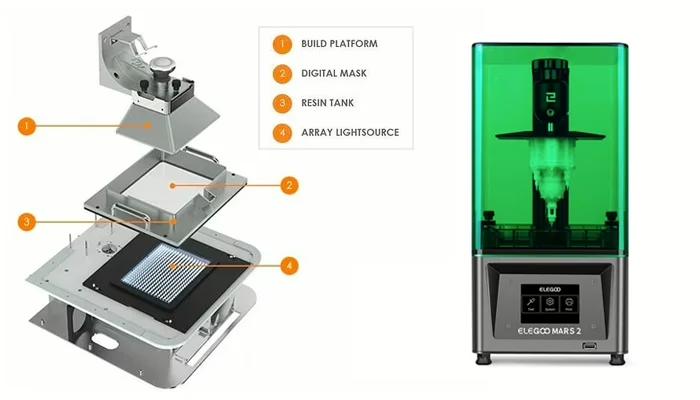

Liquid Crystal Display (don’t say LCD display!!!). LCD printers are the type of resin printer that uses a monochromatic display to flash UV lights in patterns to cure resin.

MSLA

Masked Stereolithography Apparatus. Another for of resin 3D printing that is essentially a single UV light source, of which incidence is masked by an LCD screen. It’s what allowed for more compact, cheaper (= for home-use!) 3D printers.

PPE

Personal Protection Equipment. Mandatory for handling and post-processing 3D printed parts, until their complete cure. Usually consists of gloves, goggles (or some sort of face shield) and masks with respirators.

Post-processing

Can either mean the procedures required to make 3D printed objects out of resin safe to handle (washing and curing) or those involved in bettering it aesthetically, such as cutting, filing and sanding support leftovers of imperfections.

Print Dimensions

When looking to buy a 3D printer, that’s the biggest possible size of an object that will come out of it.

Resolution

Indicates how small the details produced in the horizontal plane can be given to a certain object. The bigger the better for an equal screen size, and that’s where you’ll see terms also present in TV or phone screens: 4K, 6K, 8K…

Resin

Thick liquid that gets polymerized into a solid in a 3D printer. There’s an article written by a very handsome person on the many different types of resin and their diverse applications.

Slicer

A type of software constantly used in 3D printing that takes a virtual 3D object and converts it into instructions for manufacturing with a 3D printer. In this type of program you can tweak layer heights, exposure times and support configurations.

STL

One of the many possible file formats often used for 3D models to be printed. Others, but not all of them, can be .3MF, .3DM and .3DS.

Supports

Temporary structures that will be printed with an object that can be snapped off afterwards. These ensure all pieces will be precisely connected later. They can be generated in the Slicer software (see Slicer) or built into the model itself.

Vat

Often called build tank or resin tank. Sealed underneath with the FEP film, where it makes contact with your UV light source.

Voxel

A 3D pixel, the smallest unit of volume the printer can reproduce accurately.

As always, I’m hoping this list has been helpful in giving basic terms and definitions that will help guide you into this activity. Most of these terms have their own sub-definitions, specializations, niche use-cases and the like, but you can slowly build up your vocabulary. If I may provide some motivation on learning the ins and outs of 3D printing, why don’t you check out some 3D printer models, the best types of resin for printing miniatures, and how to remove support marks from your models? Good printing!

Loot Studios can help you paint highly detailed minis, statues, and props. Choose your favorite bundle from our previous releases or sign up for Fantasy or Sci-Fi to receive a new bundle every month. You can also check out some tips on our YouTube Channel.